AAC Block Manufacturing

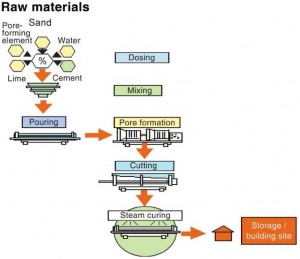

AAC blocks are manufactured through a reaction of aluminium powder and a proportionate blend of lime, cement, and fly ash or sand. The manufacturing process is clean and does not emit any hazardous chemicals. Major raw materials used for AAC block manufacturing are industrial wastes like fly ash and gypsum. The manufacturing process is energy efficient.

AAC can be produced in:

| Fly-ash Series | Sand Series |

|---|---|

| Fly-ash | Sand |

| Quicklime | Quicklime |

| Cement | Cement |

| Gypsum | Gypsum |

| Aluminium Powder | Aluminium Powder |

Raw Material Quality Requirements:

| Flyash | carbon content of less than 4 percent, SiO2 content in fly ash more than 52%, Loss on Ignition ≤ 7%, radioactive should be in line with provisions of GB6763. |

|---|---|

| Cement | should meet the national standard is 325 or # 425 # ordinary portland cement or Portland cement. |

| Quicklime | should meet JC/T621-1996 (Portland building products with quicklime)standard. |

| Gypsum | CaSO4·2H2O>70%. |

| Aluminum powder (Water dosage form) | according to JC/T407-91 standard (aerated concrete aluminium powder) with 95% purity |

Production Parameters

- Basic mix ratio

- Fly ash or Sand: Lime: Cement: Gypsum=69: 20: 8: 3

- Aluminum is about 0.08% of total of dry material

- Water ratio: 0.6~0.65

- Note: special reference should be adjust according with actual situation of raw material

- Cycle of mixing and pouring: The cycle of mixing and pouring is 5.5minutes

- The complete rest of blocks

- Time: 2-3 h

- Temperature: about 40 C

- Pressure :0.3~0.5 Mpa

- Cycle of cutting: 5.5 minutes

- Autoclave system

- Evacuation: 0~-0.06 Mpa 0.5h

- Boost pressure: -0.06~1.3 Mpa 1.25h

- Isopiestic pressure: 1.3 Mpa (temperature is about 183) 7.0h

- Depressurization: 1.3 Mpa~0 1.25h

- Total: 10h

- Coal consumption: 24kg/ m3

AAC manufacturing plants are simple in operation

- Preparation of the raw material

- Fly ash(sand), gypsum: The slurry is the admixture of fly ash (sand) and gypsum. Mixed fly ash (sand) and gypsum in a certain proportion in the slurry mixer tank, and then add water into slurry; finally, we can get the appropriate concentration slurry, and then it will be pumped by slurry pump into slurry tanks for pouring.

- Quicklime: Massive quicklime is transported and stacked in the lime material shelter. The lime block is broken by a jaw crusher, and then the belt conveyor will deliver it into the ball mill; the ball mill will grind the lime into powder. Finally, the lime powder will be elevated into lime powder silo for reservation.

- Cement: Use of bulk cement. Bulk cement is transported to the plant site by truck and then pumped directly into cement silos for reservation.

- Aluminum Powder: Aluminum powder or aluminum powder (paste) in barrels purchased from the market are stored in aluminum powder warehouses. The worker will weigh it, and then put it into an aluminum mixer, then make a 5% suspension for reservation.

- Recirculating slurry: Trims and scraps from cutting will fall into the chute under the cutting machine. The water washes the scrap into the waste slurry tank. After mixing to a certain concentration, the waste slurry pump will pump it into the waste slurry tank.

- Batching, Mixing, Pouring and Pre-curing

- Lime and cement was delivered into electronic powder scales by single screw pipe feeder. Through cumulative measurement, the unloading devices will dump them into the pouring mixer.

- Through the slurry tank valve, the fly ash (sand) pulp went into the slurry tank, and then pumped into the ingredients ceiling for measurement by electronic scale; when the weight of slurry achieved the requirement; the automatic control system stopped putting slurry down by turning off the tank valve. The measured slurry will be put into pouring mixer.

- Aluminum is measured by manual, and then put into an aluminum mixer for making suspension which was once per mold. The beaten suspension was put into the pouring mixer directly.

- The temperature of the slurry should be reached before pouring.If the temperature is not enough, it could be heated by steam. When pouring, ferry carts carry the mold to the position under the pouring mixer, and then the pouring mixer puts slurry into mold for pouring. After pouring, the mold with slurry will stay in the pre-curing room for 2-3 hours. During this period, the aluminum powder will react, and the hydrogen will be released under the action of Si and Ca material. The slurry will become the solid cake, and the volume expands.

- Cutting and Grouping

- After pre-curing and reaching the cutting intensity (tested by a special instrument or determined by production experience), the cake will be transported to the cutting position through a turning crane. The turning hoister will turn the mold 90 degrees and strip off the mold frame, and the cake will stand in the side plate. Finally, the longitudinal cutter and traverse cutter will cut the cake. After the cake is cut, the crane will transport it to the hardening carriage and group it in front of the autoclave.

- Curing and Leaving autoclave

- The low speed winch will load grouped cake to the autoclave for curing. The cake will be in an isopiestic pressure environment for about 7-10 hours, and the vapor pressure is 1.3Mpa. The temperature of the autoclave is about 190℃–210℃. Cured cake will be pulled out of the autoclave by low speed winch, and the end product will be transported manually to truck or store at the storage yard. Then the hardening carriage and side plate will be returned for recycling. Then the worker will assemble the mold with a mold frame and side plate, and clean and oil it for a new round.

- Reclamation system of waste slurry

- After cutting, the wet waste slurry will fall into the pond under the cutting machine. The water will wash it into a waste slurry mixer. Then mixed each other until they reach the concentration, it will be pumped into the batching section for reservation. According to the requirement of pouring, the waste slurry will add the appropriate proportion of raw material, and then for recycling use.